In this thrust we develop methods for the mass production of targets for Inertial Fusion Energy (IFE).

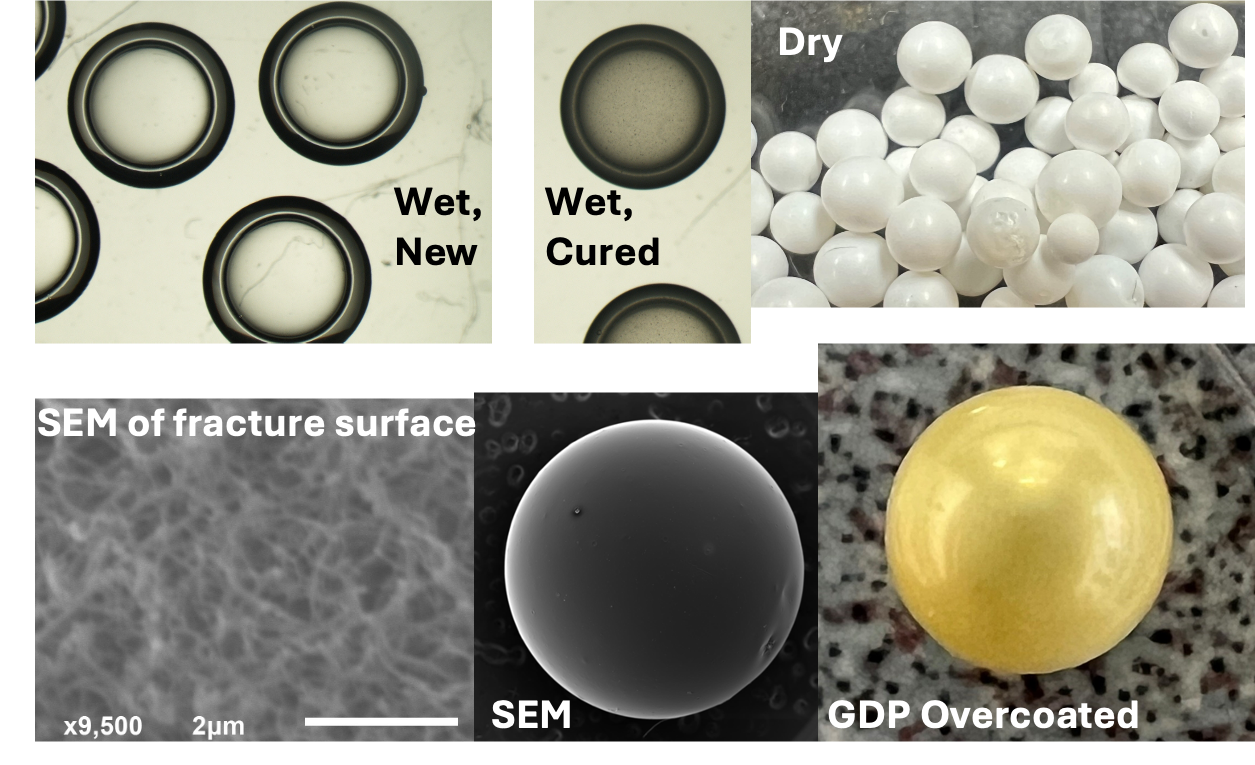

General Atomics’ efforts concentrate on the production of wetted foam shells using microencapsulation of organic aerogels, which can produce foams with very small pore size at low density. The first-of-a-kind production by microencapsulation of foam shells made from dicyclopentadiene (DCPD) was demonstrated. The foam shells are being formulated for a density of ~25 mg/cc with sub-micron pore size. An over-coat of glow discharge polymer (GDP) has been placed onto a DCPD foam shell. Formulation and procedures are being refined to improve shell quality.

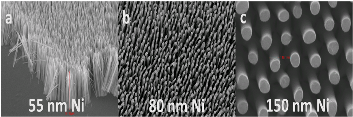

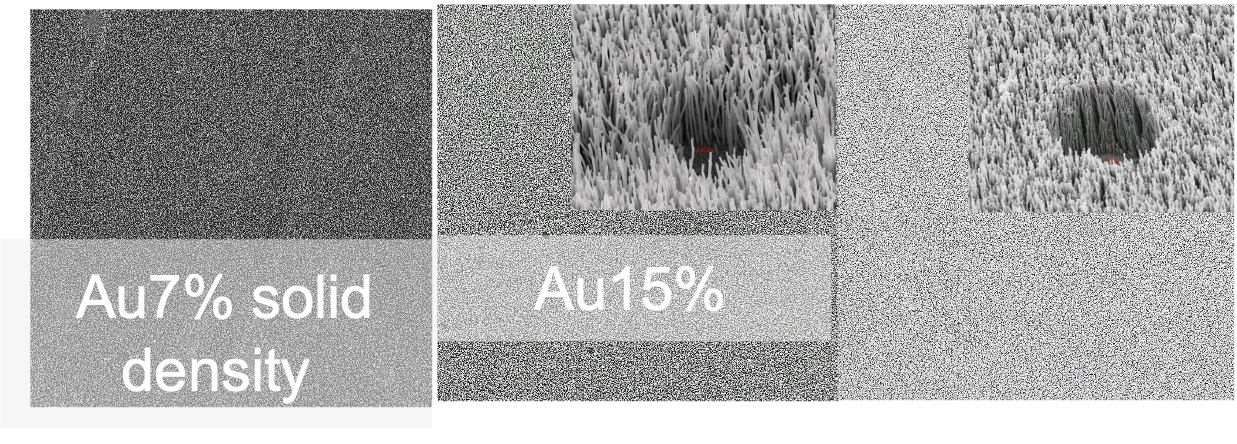

CSU fabricates nanowire arrays (NWA) of metals and polymers using a process that involves growing up through or extruding into arrays of holes in produced nanoporous anodic aluminum oxide templates. Using these processes, deuterated plastic and metallic nickel and gold NWAs were fabricated for experiments at ALEPH and LCLS to better understand the ultrafast evolution of plasmas generated from NWAs for IFE. A batch of the deuterated targets was delivered to Marvel Fusion for an experiment with the 10 PW laser at ELI Nuclear Photonics in Hungary.

Wetted foam shell from dicyclopentadiene (DCPD)

Nickel nanowire arrays (NWA)

Gold nanowire arrays (NWA)